- Machine Information

- Machine Features & Benifits

- Machine Application

- Purchase history

- Customer Reviews

- Buyers Q & A

- Related products

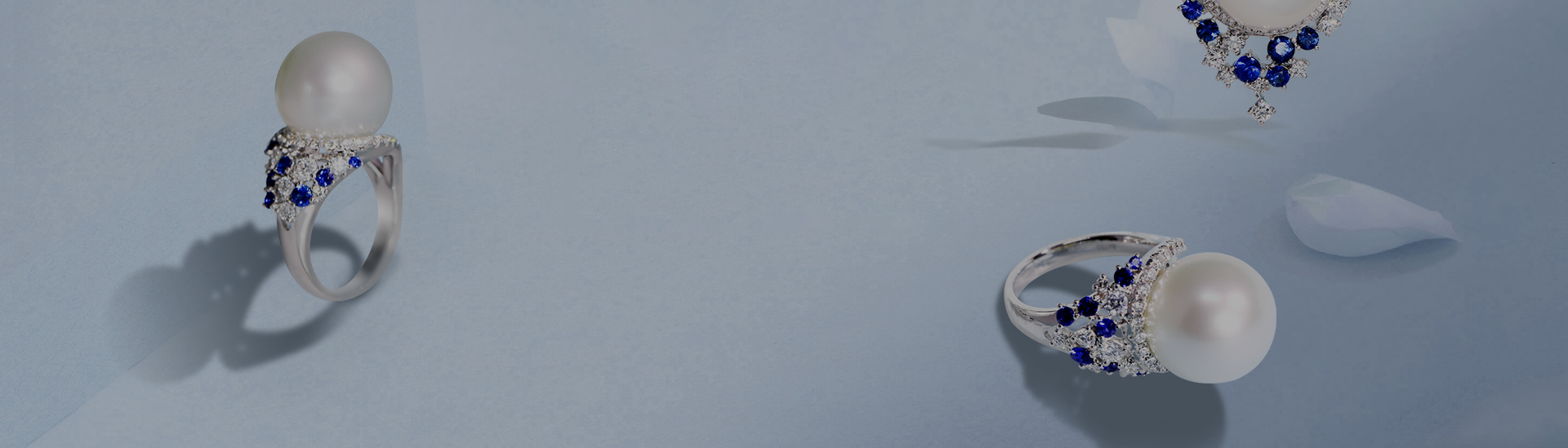

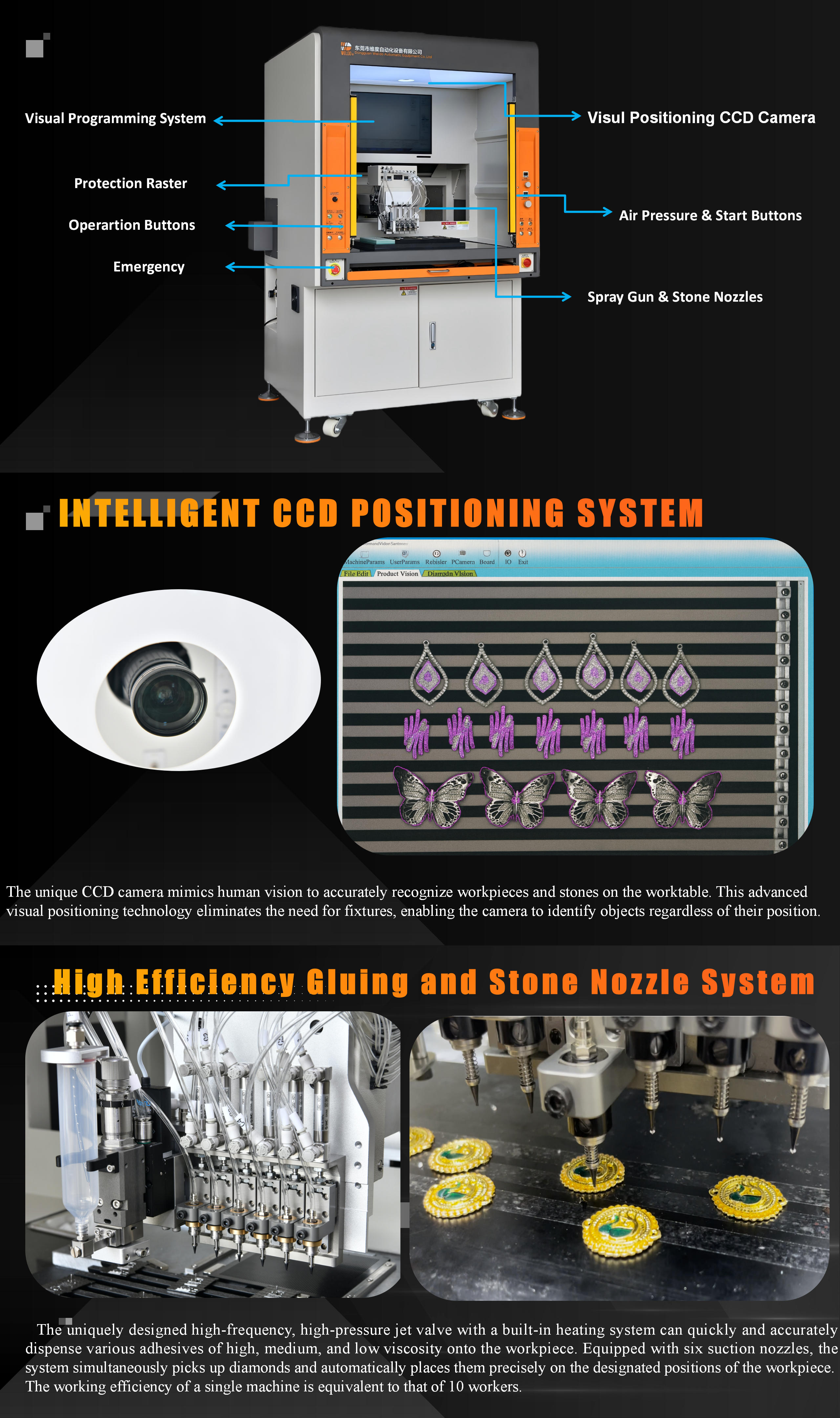

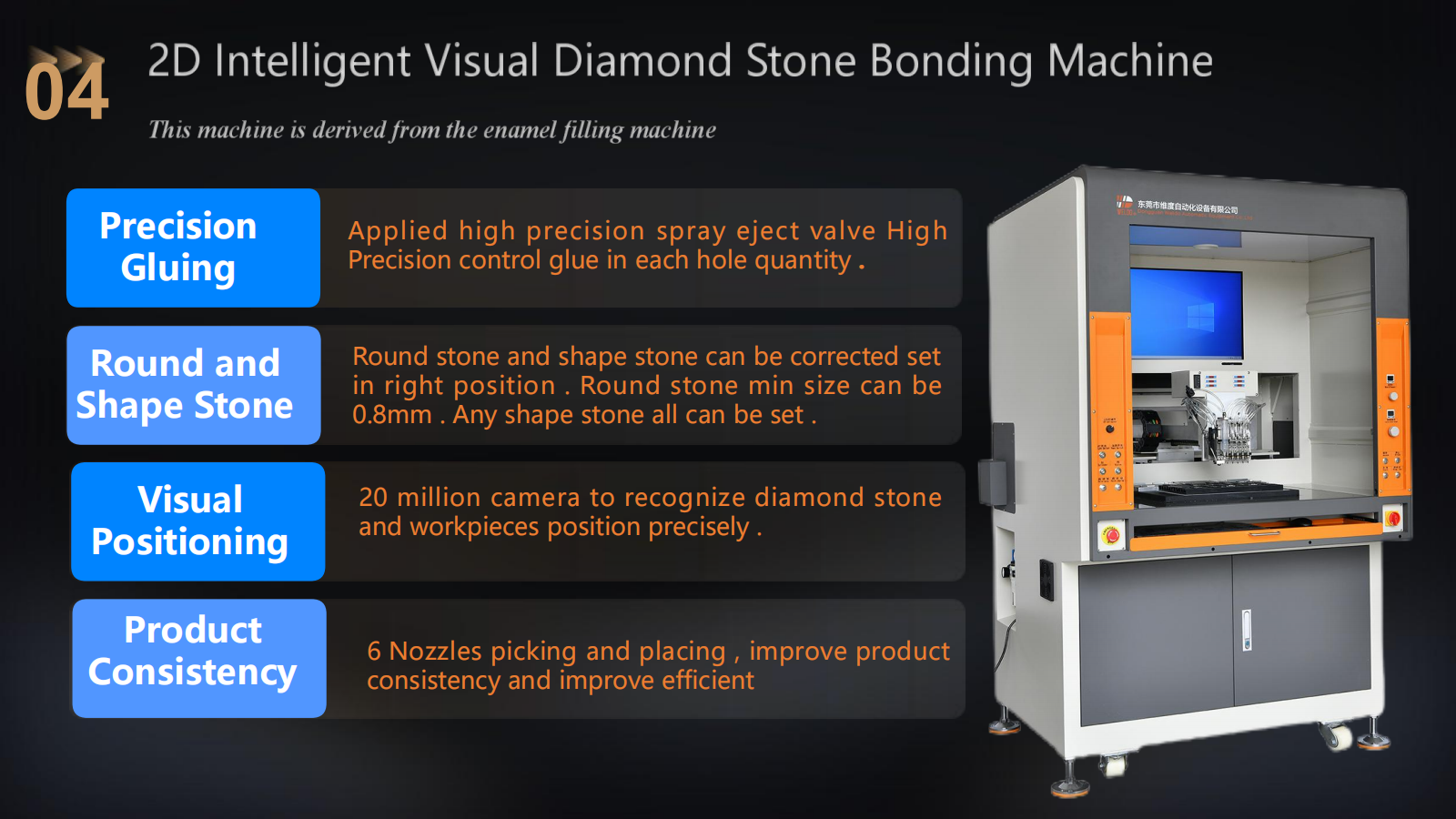

The Intelligent Visual Diamond Stone Bonding Machine is a high-precision automated solution designed to set up to six different sizes and multicolor diamond stones on various items such as ear studs, pendants, metal tags, bracelets, charms, branded fashion metal accessories for shoes and garments, and even customized automotive logos.

Utilizing advanced visual positioning technology, this machine accurately detects the positions of both the stones and the workpieces placed on the worktable, ensuring precise and efficient stone placement. Its automatic operation streamlines the bonding process, significantly enhancing productivity and consistency for fashion and accessory manufacturing.

Operation Process of Intelligent Visual Diamond Stone Bonding Machine For Kids Ear Stud Flower Jewelry Diamond Stone Automatic Setting

|  |  |  |

Technical Parameter

| Model | WD600-VD |

| Running Distance | X : 600mm, Y : 480mm , Z : 50mm |

| Worktable Max Size (mm) | 500*400 |

| Precision Nozzle Quantity (Set) | 1 Set Gluing Spray Nozzle |

| Eject Precision | 0.001ml |

| Repeat Accuarcy (mm) | +/-0.015mm |

| Camera Position Accuracy (mm) | +/-0.02mm |

| Camera Resolution ( px ) | 2 Million |

| Working Speed | 60m/min |

| Power | 220V , 3KW , 50/60 Hz |

| Transmission | Screw Balling and H level Screw Balling |

| Motor | FUJI SERVO MOTOR |

| Penumatic Components | TAI WAN AIR TAK / JAPEN SMC / GERMANY FESTO |

| Machine Size (cm) | 134(L)*133(W)*205(H) |

| Machine Weight (kgs)) | 820 |

Why Choose Intelligent Visual Diamond Stone Bonding Machine

Weldo, as a global leader in the development and manufacturing of intelligent visual diamond stone bonding machine, integrates advanced AI technology—the "brains and eyes"—into our Jewelry diamond setting robot. This ensures intelligent visual recognition and precision stone bonding, setting a new standard in the jewelry manufacturing industry.

| Strong R & D Team |

Led by our boss Doctor Lee , our R&D continuously drives innovation , keeping our machine technology ahead of the competition. | |

| Standardized Manufacturing |

Our standardized manufacturing process follows the ISO 9001 quality system , ensuring high quality and Jewelry diamond setting robot. | |

| International Technical Support |

From pre-sales consultation to post-sales service , our technical supports ensures reliability and boosts customer trust in selecting our Jewelry diamond setting robot . | |

Key Specification of Intelligent Visual Diamond Stone Bonding Machine

Integrated Design for Precision & Efficiency

The machine is composed of two main parts:

Visual Positioning System – to recognize and align stones and workpieces.

Gluing & Stone Placement System – to dispense glue and accurately pick and place stones with rotary nozzles.

This seamless integration allows the system to operate with exceptional speed, stability, and precision, making it an essential tool for modern jewelry manufacturers.

Automatic Diamond Stone Setting Machine Spray Valve Cleaning Process

Automatic Diamond Stone Setting Machine Technical Advantage

FAQ Of Automatic Diamond Gemstone Setting Robot

1. Q: If we have the stones of different sizes ,can your intelligent visual diamond stone bonding machine used for setting them at the same time?

A: Sure, one nozzle can be used with three similar types of stones.

2. Q: What is the purpose of the lower camera in intelligent visual diamond stone bonding machine

A: We use the camera below to adjust the position of the suction nozzle and determine the zero point.

3.Q:What is the maximum size of drill plate that can be placed in your machine's drill plate position?

A:48mm*48mm

4.Q:How many different colors of stones can your machine stick several at the same time?

A: 1-6 different stones .

5. Q: Does your machine's suction nozzle have intelligent vacuum detection?

A: Yes, the vacuum generator is equipped with intelligent vacuum detection.

6.Q: How many diamonds can your machine set in one second?

A:6 stones

7.Q: What is the working area of your camera?

A: 400mm*500mm

8. Q:Does your intelligent visual diamond stone bonding machine have any parts that are prone to damage?

A: Yes, but we will provide spare parts for consumable parts such as suction nozzles, sealing rings, and syringes for 3-6 months.

9.Q: If we purchase your intelligent visual diamond stone bonding machine , can your technicians come to our country to teach our workers how to use the machine?

A: We can provide on-site service in your country, but your company will need to pay for travel expenses and engineer wages.

10.Q: If there is a problem with the machine and we cannot fix it, and you are far away from us, what should we do?

A: 1. We will send experienced engineers to provide remote guidance via video.

2. For program issues, we can remotely control the machine using its camera to resolve the problem.

11. Q: Can you help send to me the 2D and 3D drawing of round stone aluminum plate?

A: Yes,with PDF

12. Q:May you help send to us the a) Mechanial Machine drawing, b) Electrical machine drawing c) the recommendate preventative mainternance plan?

A: OK you can download the design drawing

13. Q: Regarding to piezo electronic valve eject nozzle, machine will included nozzle size 0.15mm. Do you have other type of nozzle diameter? In case we need to order, will you prove to us piezo electronic valve eject nozzle?

A:We have the sizes of 0.1mm,0.15mm,0.2mm,and you can choose what you need.

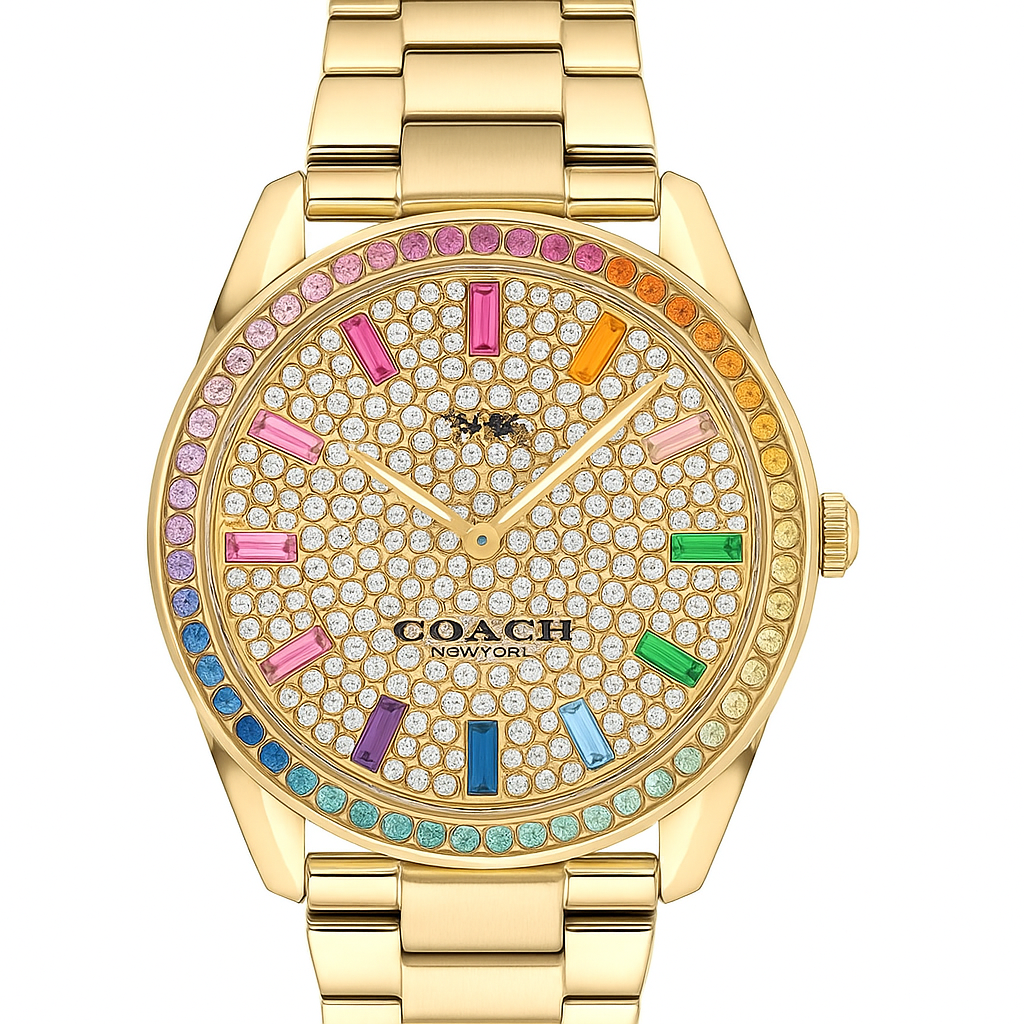

Application Fields of Intelligent Visual Diamond Stone Bonding Machine

The intelligent visual diamond stone bonding machine can bond rhinestones onto various base materials. It is widely applied in rhinestone setting for fine jewelry, high-end footwear and fashion accessories as well as decorative promotional gifts.

|  |  |

| Gifts | Watches | Car Logos |

|  |  |

| Jewelry Necklaces | Brand Fashion Clothes Buttons | Brooches |

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

The 2D Camera Positioning Automatic Shape Stone Setting Machine is engineered to efficiently fill glue and bond various crystal-shaped diamond stones. Equipped with a high-resolution CCD camera, it accurately identifies the positions of both stones and products on the worktable. Its high-precision spray valve rapidly dispenses glue into the stone holes, while four rotary stone nozzles precisely pick and place the stones into position.

This jewelry diamond setting robot is ideal for setting crystal diamond stones on silver jewelry, imitation jewelry, high-end fashion accessories, as well as gifts and handicrafts.¥0.00¥0.00 -

Jewelry Enamel Coloring Machine is a high-precision, intelligent visual automatic enamel-filling robot designed for silver jewelry accessories such as rings, charms, metal tags, pendants, necklaces, bracelets, bangles, and brooches. This advanced enamel coloring robot significantly enhances production efficiency, making it ideal for mass production—especially for seasonal and festive collections like Christmas jewelry and other holiday-themed designs.

¥0.00¥0.00 -

The 3D Jewelry Wax Stone Setting Machine offers high precision and user-friendly operation, specifically designed for inlaying Moissanite or Synthetic Cubic Zirconia (CZ) into wax molds. Ideal for producing trendy jewelry such as hip-hop style rings, this machine ensures efficient and accurate stone setting. Perfect for crafting detailed 925 Sterling Silver gemstone rings, it enhances both productivity and design quality in modern jewelry manufacturing.

¥0.00¥0.00